Pressed Metal Gable Ends – Made in Australia from Mill Grade Aluminum.

Description

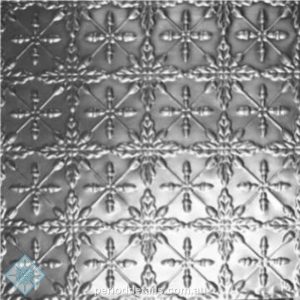

Acorn pattern. This pattern is great on kitchen splashbacks and gable ends.

Panel Size: 6ft x 3ft (1837 x 925mm, coverage 1830 x 915mm)

Pattern Repeat: – 152 x 152mm

The Acorn panel has a continuous pattern with both a square and diamond repeat. The large motif consists of four stylised oak leaves and the small motif consists of four acorns. The Acorn panel is suitable for a wide range of

wall or ceiling installations and can be painted or powder coated in a myriad of colours. Suggested usage includes: ceilings, gable ends, retaining walls, feature walls, kitchen splash backs, bathrooms, counter fronts and many more.

Panel Specifications:

-Panels are made from a specialized, mill grade aluminium that is approximately 0.55mm thick.

-Panels are treated with a non-chromate treatment which prepares the surface for subsequent priming and painting or powder coating.

-Painting or powder coating is recommended as without it panels are porous and surface scratches may be present as a result of the manufacturing process.

How many panels do I need?

We are here to help you. For a quick quote phone, text or email through your measurements.

Powdercoating:

We recommend powdercoating sheets for use as a Kitchen Splashback. Powdercoated sheets can be easily wiped clean with a micro-fibre cleaning cloth or warm soapy water.

We powdercoat with colours from the Duralloy, Precious and Electro Range.